Researchers Yizheng Wang, Timon Rabczuk, and Yinghua Liu have introduced a groundbreaking approach to friction modeling in robotic systems. Their work, published in a recent study, focuses on overcoming the limitations of traditional static friction models, such as the Stribeck model, which often require predefined functional assumptions. This can be problematic when dealing with unknown functional structures in robotic joints.

The team proposes a physics-inspired machine learning approach based on the Kolmogorov Arnold Network (KAN). This method integrates spline activation functions with a symbolic regression mechanism, allowing for model simplification and the extraction of physical expressions through pruning and attribute scoring. The result is a model that maintains high prediction accuracy while also being interpretable.

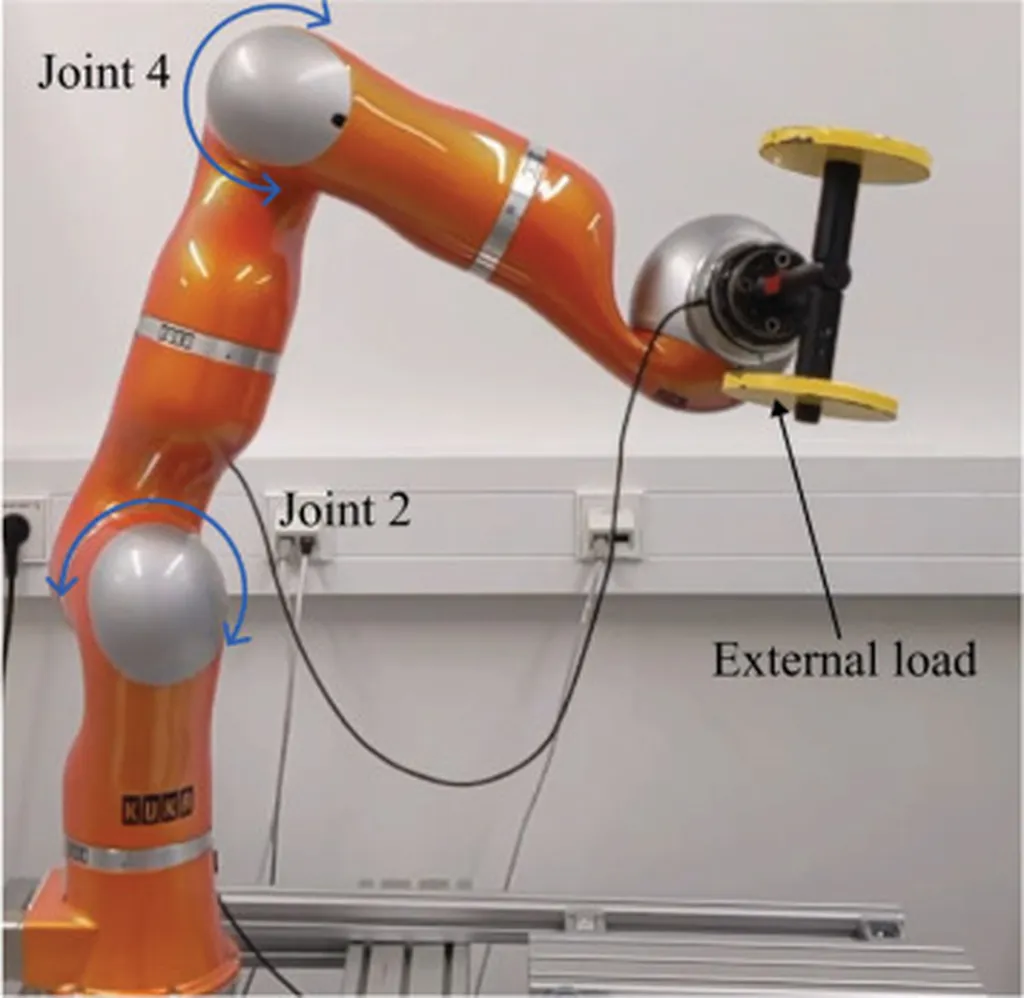

The researchers first validated their method’s capability to accurately identify key parameters under known functional models. They then demonstrated its robustness and generalization ability under conditions with unknown functional structures and noisy data. Experiments were conducted on both synthetic data and real friction data collected from a six-degree-of-freedom industrial manipulator. The results were impressive, with the proposed method achieving a coefficient of determination greater than 0.95 across various tasks. It also successfully extracted concise and physically meaningful friction expressions.

This study offers a new perspective on interpretable and data-driven robotic friction modeling, with promising engineering applicability. By leveraging the strengths of both physics-based modeling and machine learning, the researchers have developed a method that could significantly enhance the precision and reliability of robotic systems. This advancement could have far-reaching implications for industries that rely on robotic manipulators, from manufacturing to healthcare. Read the original research paper here.