In the world of marine engineering, understanding the nitty-gritty of how materials interact is crucial for building stable structures. A recent study, led by Zhiming Chao from the College of Ocean Science and Engineering at Shanghai Maritime University, has shed some light on this topic. The research, published in the journal ‘Frontiers in Marine Science’ (which, funnily enough, is not about the boundaries of the sea but a leading open-access journal in the field), focuses on the interface between marine sand and polymer layers, which are often used as anti-seepage barriers.

Now, you might be thinking, “That sounds like a mouthful. Why should I care?” Well, let me break it down for you. The shear strength of this interface is a big deal because it affects the overall stability of marine structures. Imagine trying to build a sandcastle with wet sand and a layer of plastic wrap. The way the sand sticks to the plastic wrap is similar to how marine sand interacts with polymer layers. If that interaction isn’t strong enough, your sandcastle—or in this case, a marine structure—could collapse.

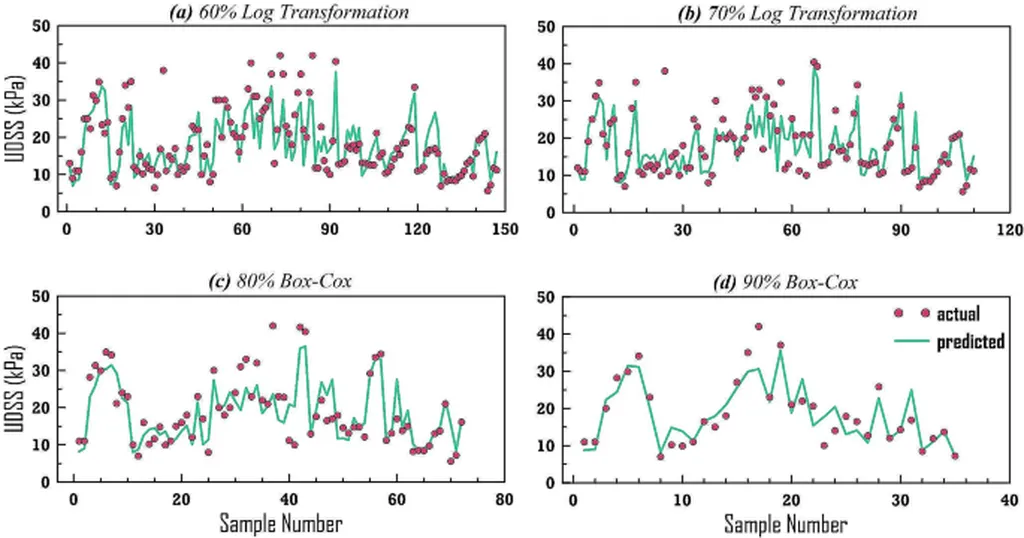

Chao and his team conducted direct shear tests at various marine temperatures to simulate real-world conditions. They collected this data to train and test different machine learning models, including Backpropagation Neural Network (BPNN), Genetic Algorithm and Particle Swarm Optimization BPNN, and Convolutional Neural Network (CNN). The CNN model, which is a type of deep learning algorithm, came out on top in terms of prediction accuracy and efficiency.

“So, what does this mean for the maritime industry?” you might ask. Well, for starters, it means we now have a more accurate tool to predict the shear strength of marine sand and polymer layer interfaces. This can help in the design and optimization of marine engineering structures, making them more stable and durable. It also provides a practical tool for those who might not be well-versed in machine learning, through an empirical formulation proposed in the study.

Moreover, this research highlights the importance of considering temperature and other factors like shear displacement, normal stress, and particle size in marine engineering projects. As Chao puts it, “The impact of normal stress is the greatest,” so it’s something that can’t be overlooked.

In simpler terms, this study is like giving marine engineers a better compass to navigate the complex world of material interactions. It’s not just about building structures; it’s about building them smarter and more efficiently. And in an industry where safety and durability are paramount, that’s a big deal.

So, the next time you’re out at sea or even just enjoying a day at the beach, take a moment to appreciate the intricate dance of materials that’s happening beneath the surface. It’s a testament to the power of science and technology in pushing the boundaries of what’s possible in marine engineering.