Researchers from Rutgers University, including Rahul Shome, Wei N. Tang, Changkyu Song, Chaitanya Mitash, Hristiyan Kourtev, Jingjin Yu, Abdeslam Boularias, and Kostas E. Bekris, have developed a robust robotic system for packing cuboid objects in logistics applications. Their work, titled “Tight Robot Packing in the Real World: A Complete Manipulation Pipeline with Robust Primitives,” addresses the challenges of picking objects from unstructured piles and arranging them tightly in bins or shipping containers. This research is crucial for improving efficiency and automation in logistics and order fulfillment processes.

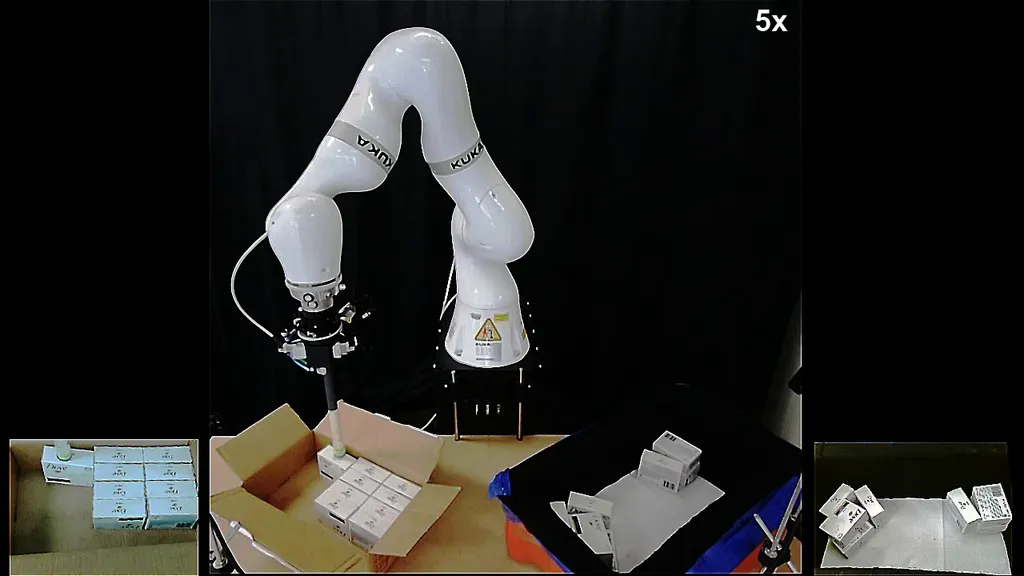

The researchers propose a comprehensive pipeline that leverages RGB-D data and a single robot arm equipped with a vacuum-based end-effector, which can also function as a pushing or dragging finger. The system integrates perception for detecting objects and planning for picking and placing them. The key challenges addressed include sensing noise and execution failures, which can occur at multiple stages of the process. To enhance robustness, the team introduced three uncertainty-reducing manipulation primitives. These primitives utilize the compliance of the end-effector and the workspace to ensure successful and tight packing of multiple cuboid objects. The overall solution is designed to be low-cost, robust, easily deployable, and simple to control, making it practical for real-world applications.

The effectiveness of the proposed pipeline and its manipulation primitives was thoroughly evaluated through extensive real-world experiments. Different versions of the pipeline were tested to assess the impact of each primitive. Additionally, an open-source simulation framework was developed to model packing operations, allowing for further experimentation and validation. Ablation studies conducted within this simulation environment provided insights into the features and effectiveness of the proposed primitives. The results demonstrate that the system is robust to both execution and perception errors, highlighting its potential for real-world deployment in logistics and order fulfillment settings.

This research represents a significant advancement in robotic manipulation for packing tasks. By addressing the complexities of sensing and execution, the proposed pipeline offers a practical solution for automating the packing process. The integration of robust manipulation primitives ensures that the system can handle the uncertainties inherent in real-world environments. As logistics and e-commerce industries continue to grow, the demand for efficient and automated packing solutions increases. This work by the Rutgers University team provides a promising approach to meeting these demands, ultimately improving operational efficiency and reducing costs in the logistics sector. Read the original research paper here.