In the quest to bolster the longevity of marine equipment, a team of researchers led by Tong Jin from the School of Electromechanical Engineering at Guangdong University of Technology has made a significant stride. Their work, published in the journal ‘Nanomaterials’ (which translates to ‘Nanomaterials’ in English), focuses on enhancing the tribocorrosion resistance of HSLA-100 steel, a material widely used in marine applications. Tribocorrosion, the combined wear and corrosion damage, is a persistent challenge in the maritime sector, leading to frequent maintenance and replacement of components.

The team engineered multilayer diamond-like carbon (DLC) coatings by alternately depositing hydrogen-free amorphous carbon (a-C) and hydrogenated amorphous carbon (a-C:H) nanolayers on HSLA-100 steel using a technique called arc-ion plating. They adjusted the modulation period, or the number of layer repetitions, from 1 to 10 cycles. This approach allowed them to fine-tune the coating’s properties, with the ten-period film (S5) emerging as the top performer.

“The ten-period film (S5) yielded the highest H/E (0.0767) and H³/E² (0.171), reflecting the best hardness–toughness synergy,” Jin explained. This synergy is crucial for withstanding the harsh marine environment, where components are subjected to both mechanical wear and corrosive seawater.

The coatings significantly reduced the dry friction coefficient to between 0.08 and 0.10, and cut wear by more than an order of magnitude compared to the uncoated steel. Moreover, the ten-period film (S5) exhibited the lowest dry wear rate (1.39 × 10⁻⁷ mm³·N⁻¹·m⁻¹) and tribocorrosion wear rate (4.53 × 10⁻⁷ mm³·N⁻¹·m⁻¹) in a 3.5% sodium chloride solution, mimicking seawater.

The secret to this superior performance lies in the interlayer interfaces. “These interfaces dissipate stresses, arrest crack propagation, and block electrolyte ingress through defects,” Jin noted. This means the coatings not only enhance the hardness and toughness of the steel but also create a barrier against corrosive elements.

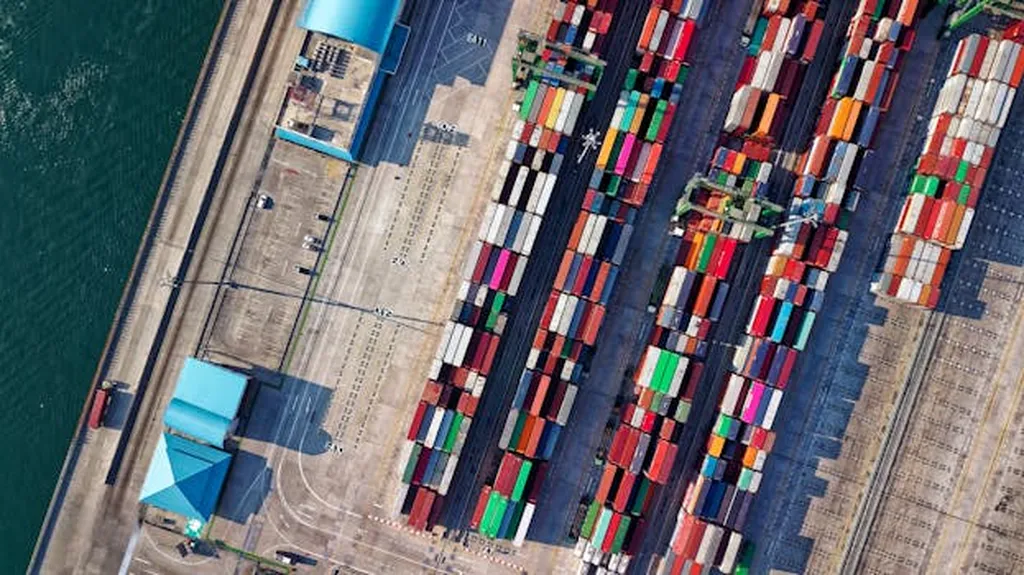

For the maritime industry, these findings present a promising opportunity. The improved tribocorrosion resistance can lead to longer-lasting components, reduced maintenance costs, and increased operational efficiency. This is particularly relevant for equipment like propellers, shafts, and other parts constantly exposed to seawater and mechanical stress.

While the research is still in its early stages, the potential is clear. As Jin and his team continue to refine their coatings, we can expect to see more robust and durable materials entering the marine market. This could be a game-changer for shipbuilders, offshore operators, and anyone involved in the maintenance and repair of maritime equipment.

In the meantime, the findings serve as a testament to the power of advanced materials science in addressing real-world challenges. By pushing the boundaries of what’s possible, researchers like Jin are helping to shape the future of the maritime industry, one coating at a time.