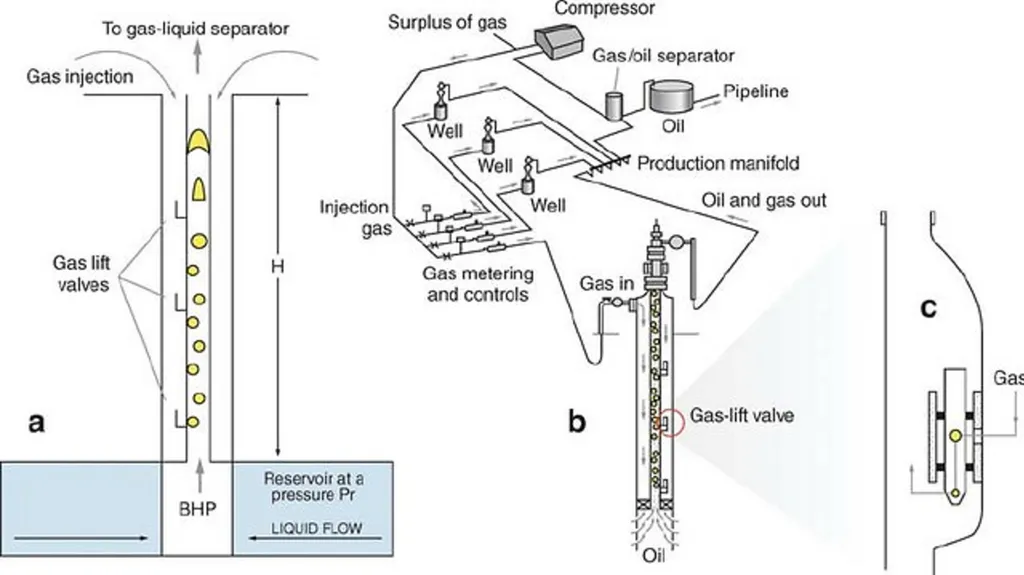

In the world of subsea resource production, getting stuff from the seafloor to the surface isn’t always a straightforward task. One method that’s gaining traction is gas-lift pumping, and a recent study published in the journal ‘Applied Ocean Research’ (or ‘Applied Ocean Research’ in English) is shedding some light on how to make this process more efficient. The lead author, Satoru Takano, from the National Maritime Research Institute at the National Institute of Maritime, Port and Aviation Technology in Tokyo, Japan, has been digging into the nitty-gritty of frictional pressure drops in these systems.

Now, you might be wondering, what’s a frictional pressure drop? In simple terms, it’s the loss of pressure that occurs as fluids flow through a pipe. This is a big deal in subsea resource production because it can affect the overall efficiency of the system. In a gas-lift pumping system, the flow inside the pipe becomes a complex mix of gas, liquid, and solid particles—a three-phase flow. Previous studies have looked at vertical three-phase flows, but the effects of pipe inclination haven’t been well understood. That’s where Takano’s research comes in.

Takano and his team conducted experiments using vertical and inclined pipes, with glass beads standing in for solid particles. They found that the angle of the pipe had a negligible influence on the interfacial-effect term of the separated-flow model they were using. In other words, whether the pipe was vertical or inclined didn’t make much difference to this particular aspect of the flow.

But here’s where it gets interesting. They developed two methods for estimating the frictional pressure drop in inclined three-phase flows. One of these methods showed a strong correlation with the experimental results, which is a big deal for the industry. As Takano puts it, “We developed two kinds of methods for estimating the frictional pressure drop of inclined three-phase flows, out of which the best-performing method demonstrated a strong correlation with the experimental results.”

So, what does this mean for the maritime sector? Well, understanding and accurately estimating frictional pressure drops can lead to more efficient subsea resource production. This could translate to cost savings and improved performance for companies involved in offshore oil and gas, as well as other subsea resource extraction activities. It’s not just about making things work better; it’s also about making them work smarter.

Moreover, as the world looks towards more sustainable and efficient ways of extracting resources, research like this is crucial. It’s about finding those small improvements that can make a big difference in the long run. And who knows? This could be just the beginning. As Takano’s research shows, there’s still plenty to learn about the complex flows involved in subsea resource production.

In the meantime, maritime professionals can keep an eye on developments in this area. With the right knowledge and tools, they can help drive the industry forward, making subsea resource production more efficient and sustainable for all. So, here’s to the researchers and professionals who are making waves in the world of maritime technology. Keep up the good work!