In a significant stride towards greener maritime operations, researchers have developed a novel hydrogel coating that promises to revolutionize antifouling strategies in the shipping industry. The study, led by Haobo Shu from the School of Mechanical Engineering at Yangzhou University in China, introduces a dual crosslinked polyvinylpyrrolidone (PVP)-phenol hydrogel coating that is not only sprayable but also boasts impressive mechanical stability and antifouling properties.

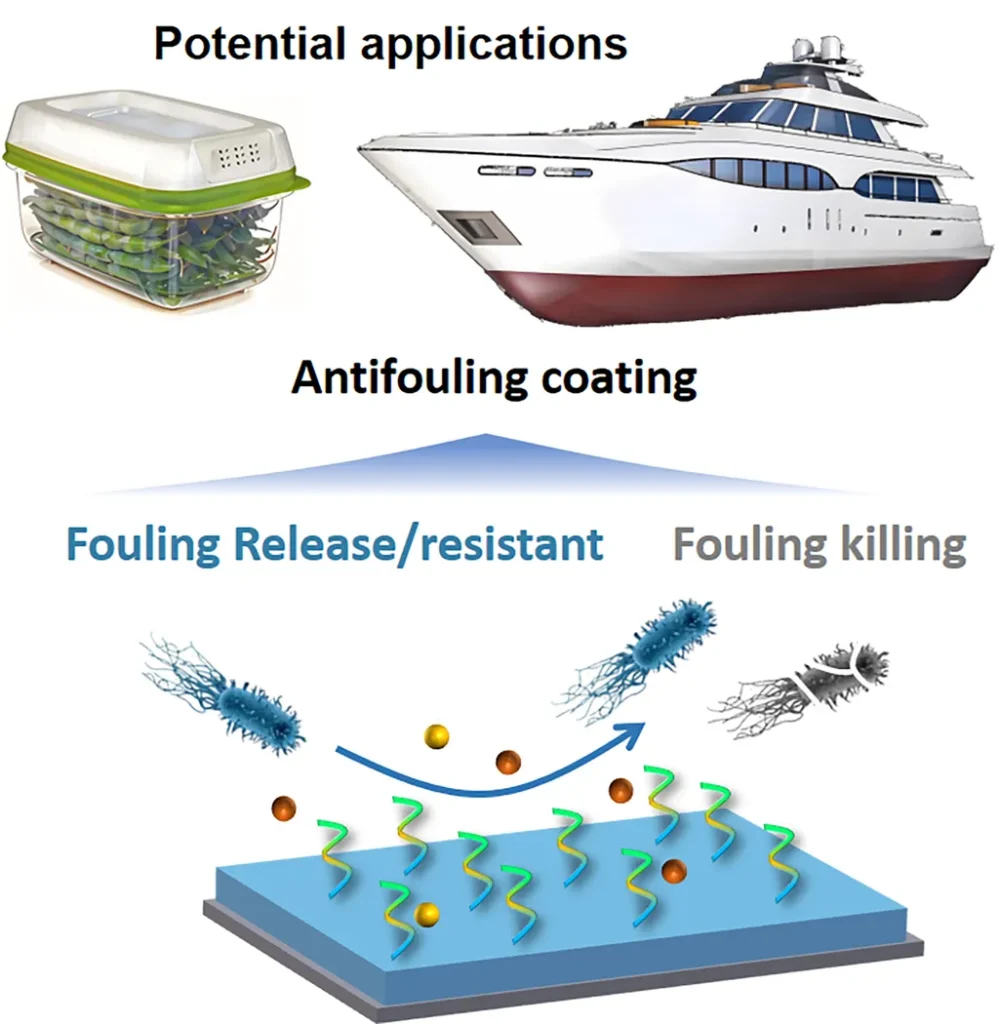

Marine biofouling, the accumulation of microorganisms, plants, algae, or small animals on wetted surfaces, poses a substantial challenge to the maritime sector. It leads to increased fuel consumption, higher maintenance costs, and even structural damage. Traditional antifouling paints, while effective, often contain harmful biocides that pose environmental risks. The new hydrogel coating, published in the journal ‘Friction’ (translated to English), offers a more sustainable alternative.

The hydrogel coating is prepared through a rapid contact molding process, resulting in a microscopic reticular structure inspired by mussel adhesion proteins. This structure enhances the coating’s hydrophobicity and waterproof adhesion, crucial for withstanding the harsh marine environment. The coating’s wet adhesion strength was measured at an impressive 3.42 MPa, indicating its stability in wet conditions.

The coating’s effectiveness was further demonstrated through various tests. It exhibited a swelling rate of less than 30%, a low modulus, and stable lubricating properties. Moreover, it showed a remarkable inhibition rate of over 99% against common ocean bacteria and algae, and an electrochemical corrosion protection rate of 63.49% on stainless steel surfaces.

The commercial implications of this research are substantial. The shipping industry stands to benefit significantly from reduced biofouling, leading to lower fuel costs and maintenance expenses. The coating’s sprayable nature and rapid molding process make it a practical solution for large-scale applications. Furthermore, its environmentally friendly composition aligns with the increasing global focus on sustainable maritime practices.

As Haobo Shu explains, “The hydrogel coating, after double cross-linking of PEI and V2O5, had a swelling rate within 30% and a low modulus along with stable lubricating properties.” This innovation not only addresses the immediate need for effective antifouling solutions but also paves the way for future advancements in marine coatings technology.

In the ever-evolving landscape of maritime operations, this research offers a promising avenue for enhancing efficiency, sustainability, and cost-effectiveness. As the industry continues to embrace green technologies, the dual crosslinked PVP-phenol hydrogel coating could well become a cornerstone of modern antifouling strategies.