In a significant stride towards revolutionizing ship design, researchers have explored the use of AI-based 3D model generators to streamline the conceptual design of ship hulls. This innovative approach, detailed in a study led by Yongyu Huang from the Faculty of Maritime and Transportation at Ningbo University, aims to reduce dependency on traditional design methods and foster creativity in hull form development.

Currently, ship hull design heavily relies on designers’ expertise, existing ship data, and commercial CAD software, often leading to prolonged design cycles and limited innovation. Huang and his team investigated the application of generative large-scale models to address these challenges. They evaluated four prominent models—Hunyuan 3D, Meshy, Rodin, and Tripo—using dual-modal inputs, including text prompts and contour sketches. The goal was to assess the accuracy of feature representation and geometric integrity under various input conditions.

One of the key contributions of this research is the development of a quantitative surface quality assessment method. This method identifies abnormal curvature regions on hull surfaces by calculating half-breadth values at mesh element centroids, incorporating multiple constraint conditions. Two indices, the special odd area ratio (SOA) and the normal odd area (NOA) ratio, were defined to objectively evaluate the fairness of generated hull surfaces. Additionally, a combined smoothing optimization pipeline, integrating Laplacian and Taubin algorithms, was developed to enhance surface quality, making the models suitable for computational fluid dynamics (CFD) analysis.

Huang emphasized the importance of these advancements, stating, “The proposed quantitative surface quality evaluation method and hybrid smoothing algorithms provide essential technical support for the engineering application of AI-generated geometries.” This approach not only reduces reliance on parent ship data and designer experience but also paves the way for innovative hull forms.

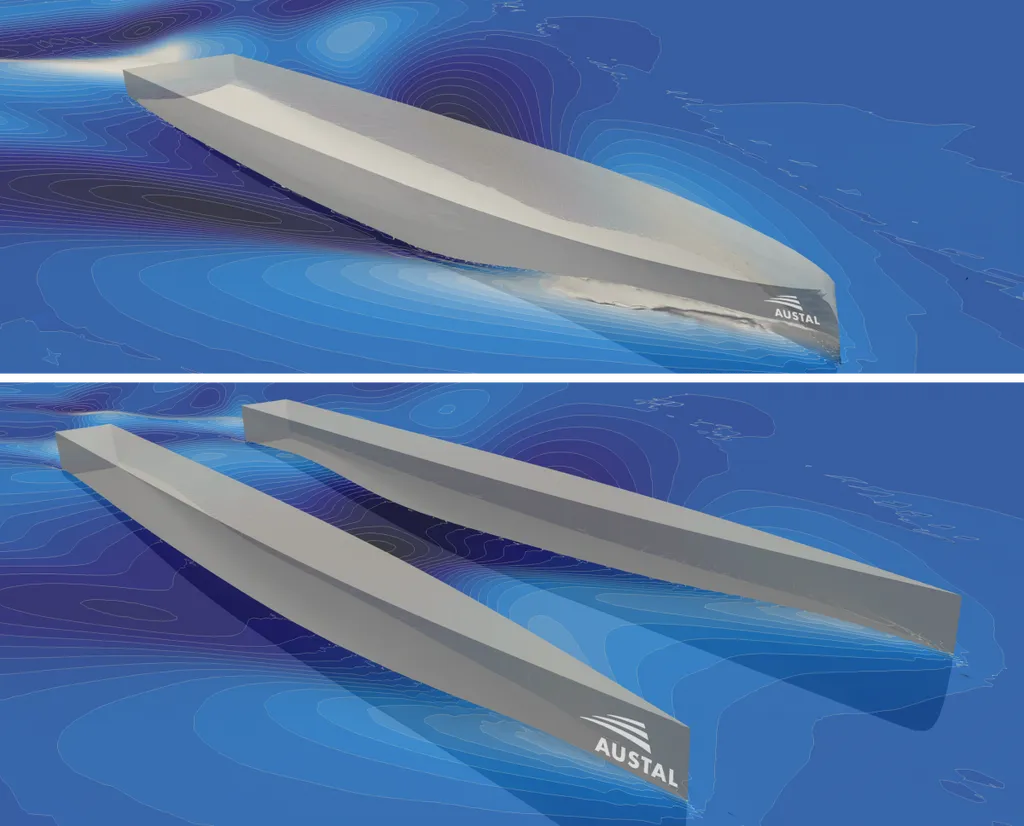

The study also included hydrostatic calculations and numerical simulations of resistance performance using STAR-CCM+. The results demonstrated that the AI-generated hull forms, after post-processing optimization, met both mesh quality and hydrodynamic analysis requirements. Notably, the optimal hull form, generated by Rodin, exhibited the lowest total resistance coefficients across all operating conditions within the Froude number range of Fr=0.20~0.30.

The implications for the maritime industry are substantial. By leveraging AI-based 3D model generators, ship designers can significantly reduce the time and resources required for conceptual design. This technology also opens up new opportunities for innovation, allowing for the exploration of novel hull forms that could enhance performance and efficiency.

As Huang noted, “This approach effectively facilitates hydrodynamic performance analyses, such as resistance evaluation, and lays a foundation for the development of intelligent hull optimization design frameworks.” The research outcomes, published in ‘Zhongguo Jianchuan Yanjiu’ (translated to ‘Chinese Journal of Ship Research’), highlight the potential of generative large-scale models in ship hull design, offering a glimpse into the future of maritime engineering.

For maritime professionals, this research underscores the importance of embracing AI technologies to stay competitive in an evolving industry. The integration of AI-based tools into the design process can lead to more efficient, innovative, and cost-effective solutions, ultimately benefiting the entire maritime sector.