In the ever-evolving landscape of industrial safety, a groundbreaking framework developed by researchers at the Arab Academy for Science, Technology & Maritime Transport is making waves. The framework, dubbed RoboFusion, is a novel approach to hazard detection and environmental monitoring in industrial settings, with significant implications for the maritime sector.

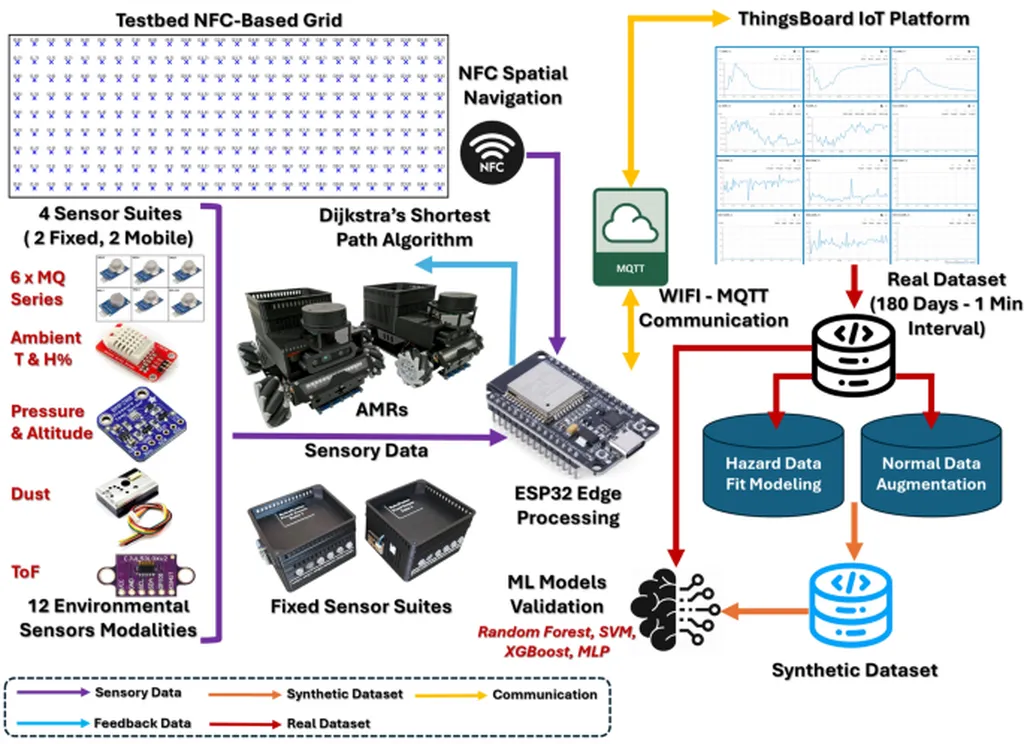

At the helm of this research is Amr Khamis, a professor in the Department of Electronics and Communications Engineering. Khamis and his team have developed a system that integrates Autonomous Mobile Robots (AMRs), fixed sensing nodes, and a unique hybrid dataset generation pipeline. This system has been deployed in a real-world industrial testbed, collecting over one million multi-modal sensor records, including temperature, humidity, gas concentrations, air quality, and pressure.

The challenge, as Khamis explains, lies in the scarcity and imbalance of hazard events in real-world data. “The rarity of hazard events makes it difficult to train effective models,” he says. To address this, RoboFusion uses a structured synthetic dataset generation framework. This framework augments non-hazardous data using statistical augmentation techniques and simulates hazardous data through multi-phase curve fitting, spatial propagation modeling, and location-aware hazard scenarios.

The results are impressive. Evaluation across four machine learning models—Random Forest (RF), Support Vector Machine (SVM), Extreme Gradient Boosting (XGBoost), and Multi-Layer Perceptron (MLP)—showed significant improvements. For instance, hazard F1 scores improved from 0.47 to 0.85 for the RF model, and from 0.16 to 0.79 for the SVM model when models trained on synthetic data were tested against real hazard events.

So, what does this mean for the maritime industry? The potential is vast. Maritime environments are often complex and hazardous, with conditions that can change rapidly. A system like RoboFusion could revolutionize safety monitoring on ships, in ports, and in offshore installations. It could enable real-time hazard detection and environmental monitoring, reducing the risk of accidents and improving overall safety.

Moreover, the commercial opportunities are significant. The maritime industry is always looking for ways to improve efficiency and safety while reducing costs. A system like RoboFusion could help achieve these goals by automating hazard detection and environmental monitoring, reducing the need for manual inspections, and improving the accuracy of safety assessments.

In the words of Khamis, “RoboFusion delivers a reproducible robotic sensing platform and an openly accessible hybrid dataset. It introduces a novel approach to hazard simulation that mimics real-world hazards and supports the development of resilient AI systems for industrial hazard detection and autonomous safety intelligence.”

This research, published in the journal ‘Scientific Reports’ (which translates to ‘Reports of Science’ in English), is a significant step forward in the field of industrial safety. As the maritime industry continues to evolve, systems like RoboFusion could play a crucial role in ensuring safety and efficiency.