In a significant stride towards sustainable oily wastewater treatment, researchers have developed a novel, eco-friendly membrane technology using jute agro-waste. The study, led by Nadeem Baig from the Interdisciplinary Research Centre for Membranes and Water Security at King Fahd University of Petroleum and Minerals, presents a promising solution for the maritime industry, where oily wastewater management is a persistent challenge.

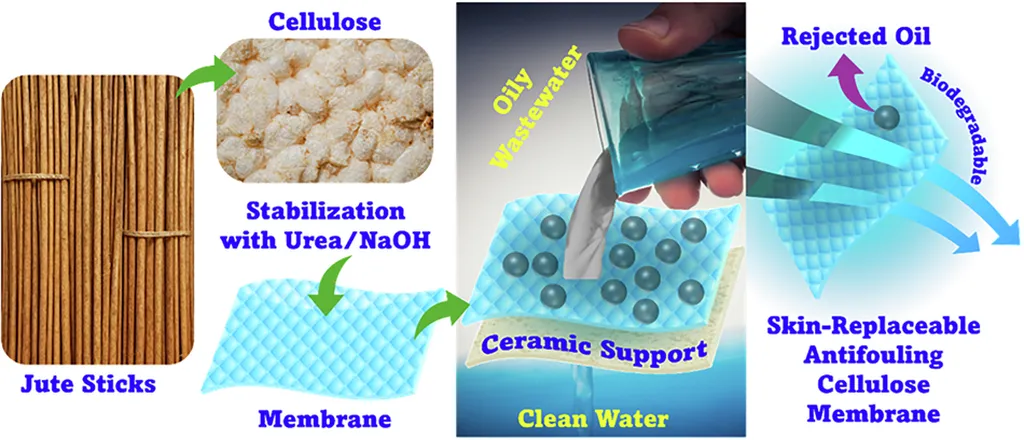

The research, published in ‘npj Clean Water’ (which translates to Nature Partner Journal Clean Water), introduces skin-replaceable cellulose membranes (SRC-M). These membranes are fabricated using a green, scalable method involving jute agro-waste, a readily available and renewable resource. The process uses a NaOH/urea activation route and argon-pressurized deposition onto ceramic supports, resulting in asymmetric membranes with high water flux and excellent oil rejection rates.

So, what does this mean for maritime professionals? Currently, oily wastewater generated from ships, platforms, and other offshore facilities poses significant environmental risks and operational costs. Traditional treatment methods often involve complex processes and high expenses. The new SRC-M technology offers a more sustainable and efficient alternative.

The membranes exhibit impressive performance, with a water flux of around 470 litres per square meter per hour and over 98% oil rejection across various emulsions. But what truly sets them apart is their self-renewable nature. The membrane’s surface can be fully renewed via ultrasonication, restoring over 99% of the original flux after multiple fouling cycles. This means extended lifespan and reduced maintenance costs, a boon for maritime operations.

“Density functional theory calculations confirm the thermodynamic stability and low kinetic barrier of urea adsorption on cellulose, supporting the dissolution mechanism and regeneration behavior,” explains Baig. In simpler terms, the science behind the membrane’s regeneration is solid, ensuring its reliability and effectiveness in real-world applications.

The commercial impacts of this technology are substantial. For maritime industries, adopting such sustainable practices can lead to significant cost savings, reduced environmental footprint, and improved regulatory compliance. Moreover, the use of jute agro-waste aligns with green chemistry principles, promoting a circular economy where waste is transformed into valuable resources.

This innovative membrane technology not only addresses the immediate need for efficient oily wastewater treatment but also paves the way for more sustainable practices in the maritime sector. As the industry continues to seek eco-friendly solutions, the SRC-M technology stands out as a beacon of progress, offering a robust, circular solution for long-term wastewater remediation.