In the world of underground construction, particularly in bustling port cities where space is at a premium, engineers often face the challenge of building new tunnels near existing ones. A recent study published in the journal ‘Scientific Reports’ (translated from Chinese as ‘Scientific Reports’) tackles this very issue, offering a more accurate way to predict how existing tunnels might deform when new ones are built above them in complex soil conditions. The lead author, Kan Huang from the School of Future Transportation at Guangzhou Maritime University/Guangzhou Transportation University (Preparatory), has developed a method that could significantly improve the safety and efficiency of such projects.

So, what’s the big deal? Well, when you’re building a new tunnel over an existing one, especially in areas with layered soil conditions—like many coastal cities—the existing tunnel can experience vertical displacement, or uplift. This is a critical factor to consider, as it can affect the safety and longevity of the existing infrastructure. Traditional methods of predicting this displacement often overestimate the movement, leading to conservative designs that can be costly and time-consuming.

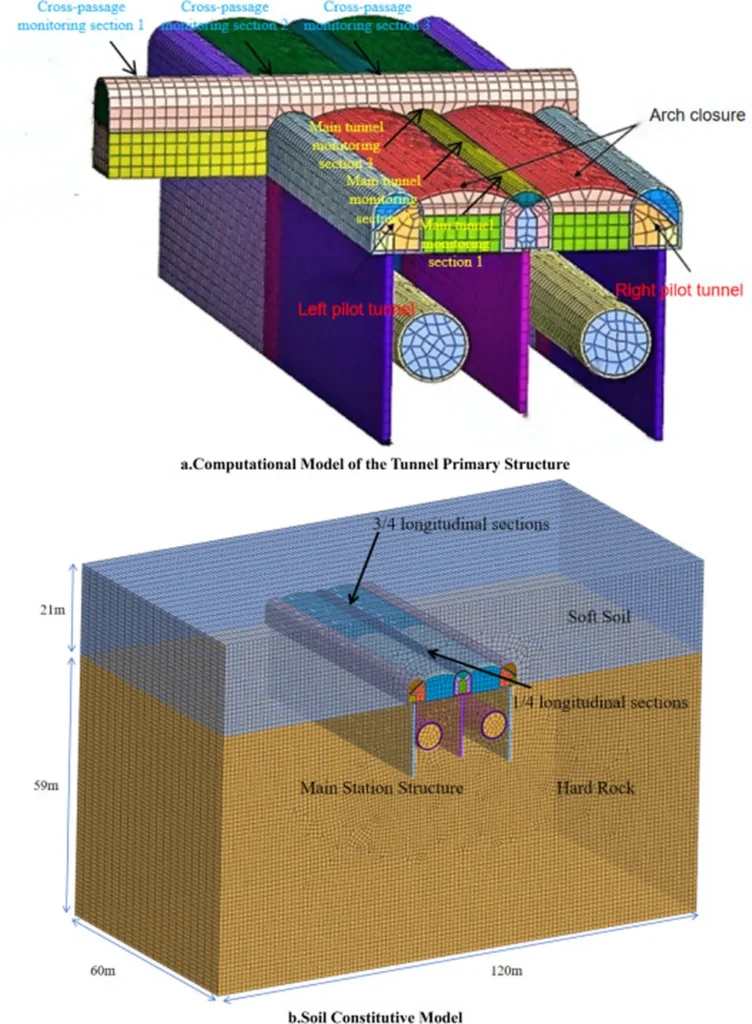

Huang’s approach introduces a more nuanced way to model the interaction between the soil and the tunnel. By treating the existing tunnel as a Timoshenko beam (which accounts for shear deformation) interacting with a Pasternak foundation (which considers the soil’s resistance to deformation), and incorporating the layered characteristics of the soil, the study provides a more accurate prediction of the tunnel’s behavior.

“The conventional soil–tunnel interaction models based on the Mindlin solution tend to overestimate the vertical displacement of existing tunnels in layered foundations,” Huang explains. “In contrast, the proposed approach yields predictions with smaller errors.”

This is where the commercial impact comes in. More accurate predictions mean that engineers can design safer and more efficient tunnels, reducing the need for overly conservative (and expensive) safety margins. This is particularly relevant for maritime sectors, where port cities often have complex underground infrastructures and are constantly expanding to accommodate growing trade volumes.

Moreover, the method developed by Huang and his team can be numerically solved using the finite difference method, making it practical for real-world applications. The study also validates the proposed method against field monitoring data and finite element analysis (FEA) results, showing a significant reduction in prediction error for maximum displacement.

For maritime professionals, this research opens up opportunities for safer and more cost-effective tunnel construction and expansion projects. As port cities continue to grow and evolve, the ability to accurately predict and manage the deformation of existing tunnels will be crucial. Huang’s work provides a valuable tool for achieving this, potentially saving time, money, and resources in the process.

In the words of the study, “the Timoshenko–Pasternak model, integrated with the elastic layered theory, provides more accurate predictions of existing tunnel deformation in layered strata compared to traditional beam–foundation combination models.” This is not just academic jargon; it’s a practical solution that could make a real difference in the world of underground construction, particularly in the maritime sector.